W1

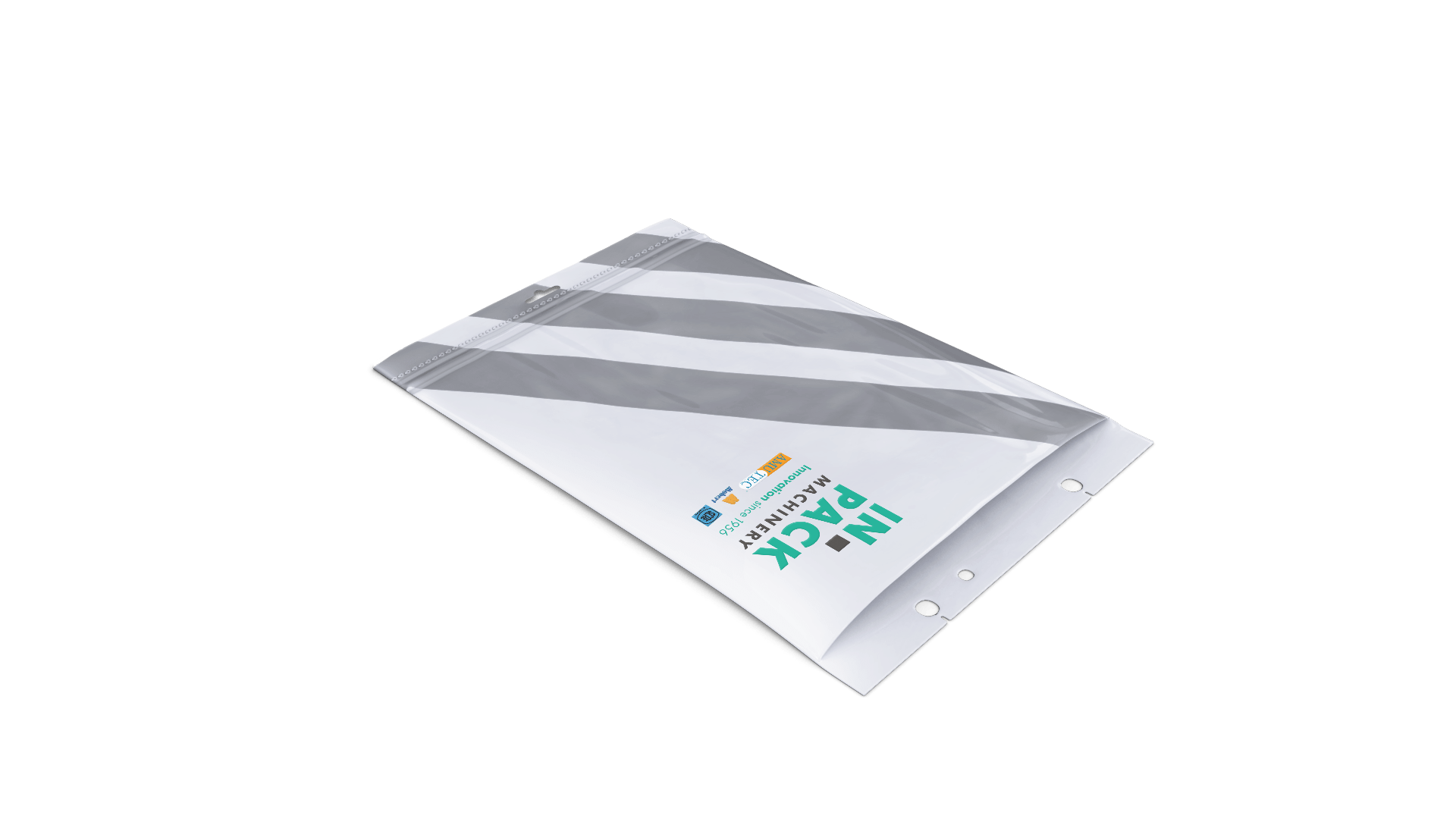

Packaging with paramount handle external to the gusset

Self-monitoring solutions for film skew and print pitch variation have been adopted in order to Automaticlly adjust the position of the accessories based on the machine’s feedback in order to guarantee the extremely tight tolerances required for this type of packaging. This maximises the productivity of the machine and gives the operator more time to carry out constant checks on product and packaging quality.

| Technical Characteristics | EHT 471 |

|---|---|

| Available width | 660 - 880 - 1100 mm |

| Minimum bag length | 100 mm |

| Maximum bag length | 600 mm (730 mm su richiesta) |

| Mechanical speed | 450 cycles/min (dipende dal modello) |

| Sliding speed | 120 mt/min |

Packaging with paramount handle external to the gusset

Scanpack with handle

Chevron-style bread ball sack

Chicken packing bag

1- and 2-track bag on pad

Bag with mesh window for fruit and vegetable packaging

Bag for product display

Bag with single fold and bottom zip

Packaging with paramount handle internal to the gusset

Packaging with strap handle or single layer handle

Packaging with cross handle or double-layer handle

Packaging for sanitary pads

Packaging with a short side handle with internal reinforcement

Packaging with a short side handle with external reinforcement

Packaging with draw tape handle

Scanpack with handle

E-commerce bag with 1 or 2 closing tapes

E-commerce bag with 1 o 2 closing tapes and V-shaped flap

Mailer bag with double document pouch

Medical specimen bag with adhesive closure